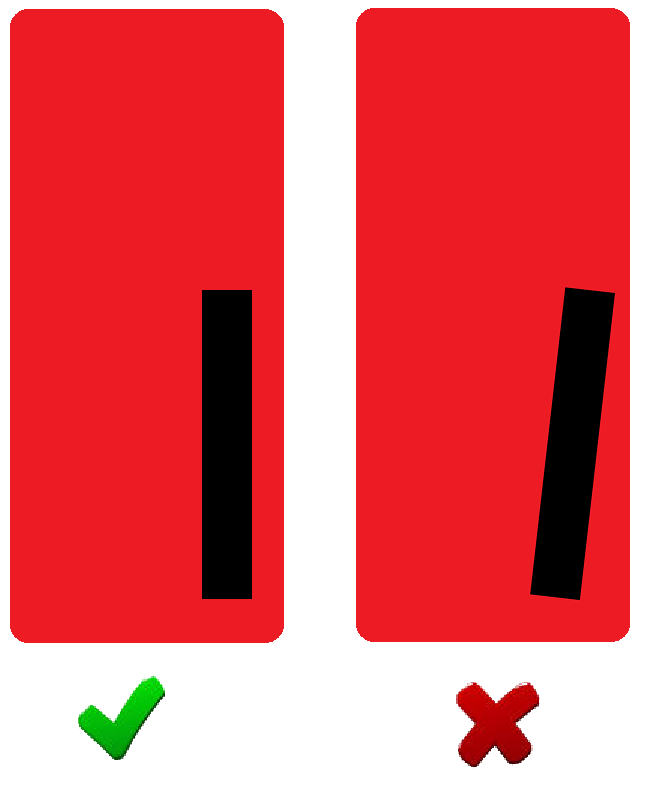

During soldering of the 40-pin header, it needs to be parallel to the board outlines:

In order to help with that, some straight lines might help align the header better. Even though silkscreen thickness varies from fab to fab (and with cheaper fabs, from board to board), it still might be a worthwhile thing to do. Maybe wavy lines could help if the line is made thicker by the fab?