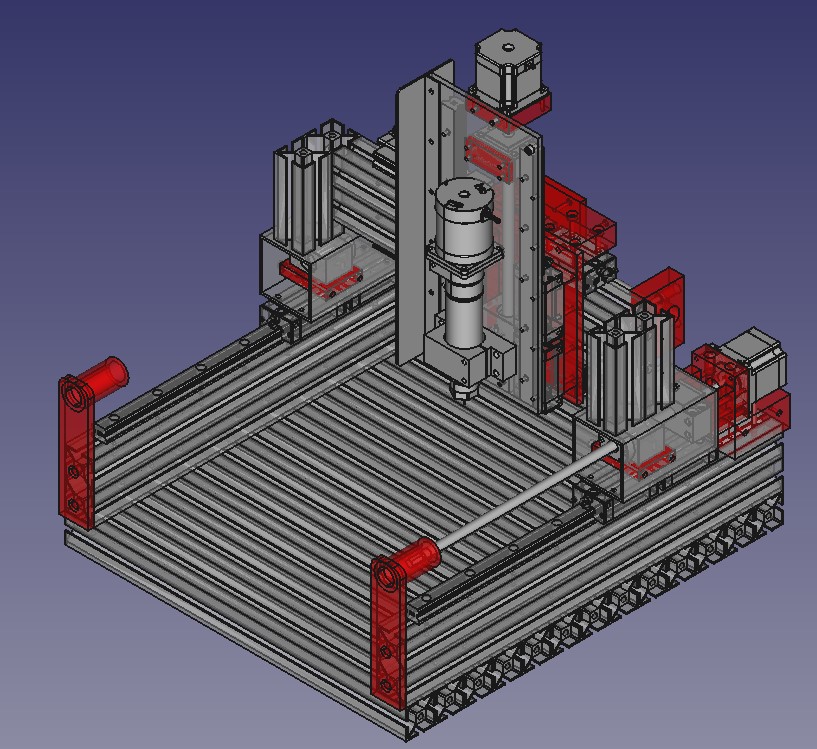

An easy to build portal milling machine for milling steel designed in FreeCad. Most parts can be 3D printed to build the machine and milled out of aluminum when the machine is done to increase regidity.

Current progress: The machine is done and is used to mill aluminum parts to replace some 3D printed parts for more rigidity. I use the router for milling aluminum and steel and making PCB's. The result is good but my manual mill is more rigid. It would take about 100 hours to redo this machine from scratch. If you have a milling machine, you could directly make the aluminum version.

Backlash on all axis is somewhere between 0.01 and 0.03 mm. I can adjust all axis to 0.02 mm / 100 mm. The repeatability on all axis is better than 0.01 mm. (That is not the same as accuracy). Without measuring, steel parts are within 0.1 mm. I haven't completed all tests but I expect that I can mill steel parts within 0.03 mm. The self made 3000 RPM ER16 spindle is realy quit when milling. Because it is made from aluminium extrusion, it makes more noise than the manual mill under the same conditions. The weight is about 55 kg.

For the next project I am going to CNC a manual mill that all ready has ball screws on the X and Y axis for more rigidity and lesser noise.

This page is under construction