-

Notifications

You must be signed in to change notification settings - Fork 0

Ocelot steering dev #1

New issue

Have a question about this project? Sign up for a free GitHub account to open an issue and contact its maintainers and the community.

By clicking “Sign up for GitHub”, you agree to our terms of service and privacy statement. We’ll occasionally send you account related emails.

Already on GitHub? Sign in to your account

base: master

Are you sure you want to change the base?

Conversation

…ty signal added. STEERING_OK redundant.

|

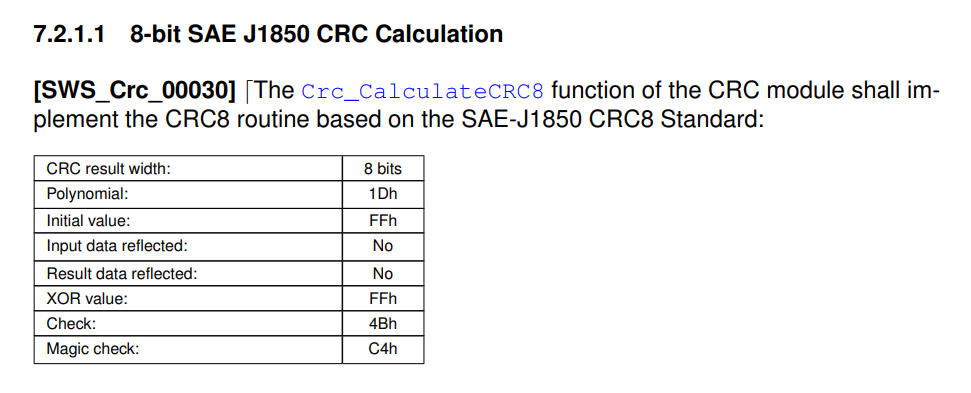

i agree with the stance that we need a standardized interface. making sure the i/o are at least somewhat consistent across setups will be a decent undertaking, so let's get the CAN side out of the way first. i suppose we don't need driver_torque, but we will need at least a one-bit message to communicate driver override somewhere. we follow J1850 for the spec, so it should be little-endian, and the checksum should be CRC8 with a poly of D5 at the top of the message (byte 0). aside from the algo, i see most of that is followed here. i have most of these reqs ported to STM32CubeIDE in another actuator project here: https://github.com/wocsor/stm32f4_steer_actuator i think we should define a few "diagnostic only" PIDs and move speed, current, temp, and other data in there. |

|

|

I removed the driver torque message. Is that what you mean by something else? |

|

CRC-8-SAE J1850 uses polynomial 0x1D, but you have it right in your c-code. The only thing is J1850 doesn't specify how to present the data to the CRC algorithm. I am currently replacing the first byte with a Msg id instead of ignoring it. Here. I looked at BMW now. They started using CRC in F-series and the algorithm uses 9 bytes. I figured that they feed CRC with 1st and 2nd bytes of msg id and then 7 data bytes. This is the proper way to do it if we bother to use CRC at all, because it is easy for the controller to send correct data but with a wrong id. |

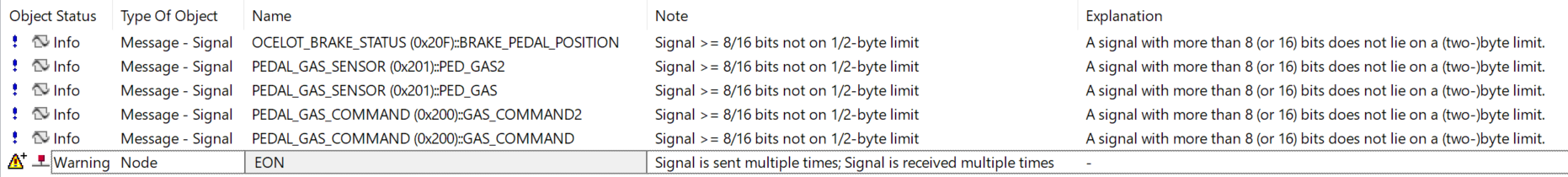

…byte limit." This reverts commit 44b7dce.

@wocsor

In my fork, I am using Ocelot-steering-dev branch.

Can we agree on a single interface before potentially more than two people start to use it?

Summary:

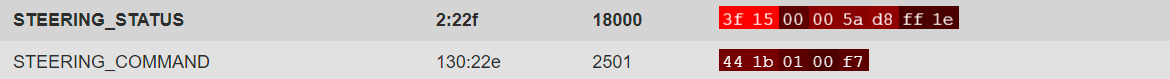

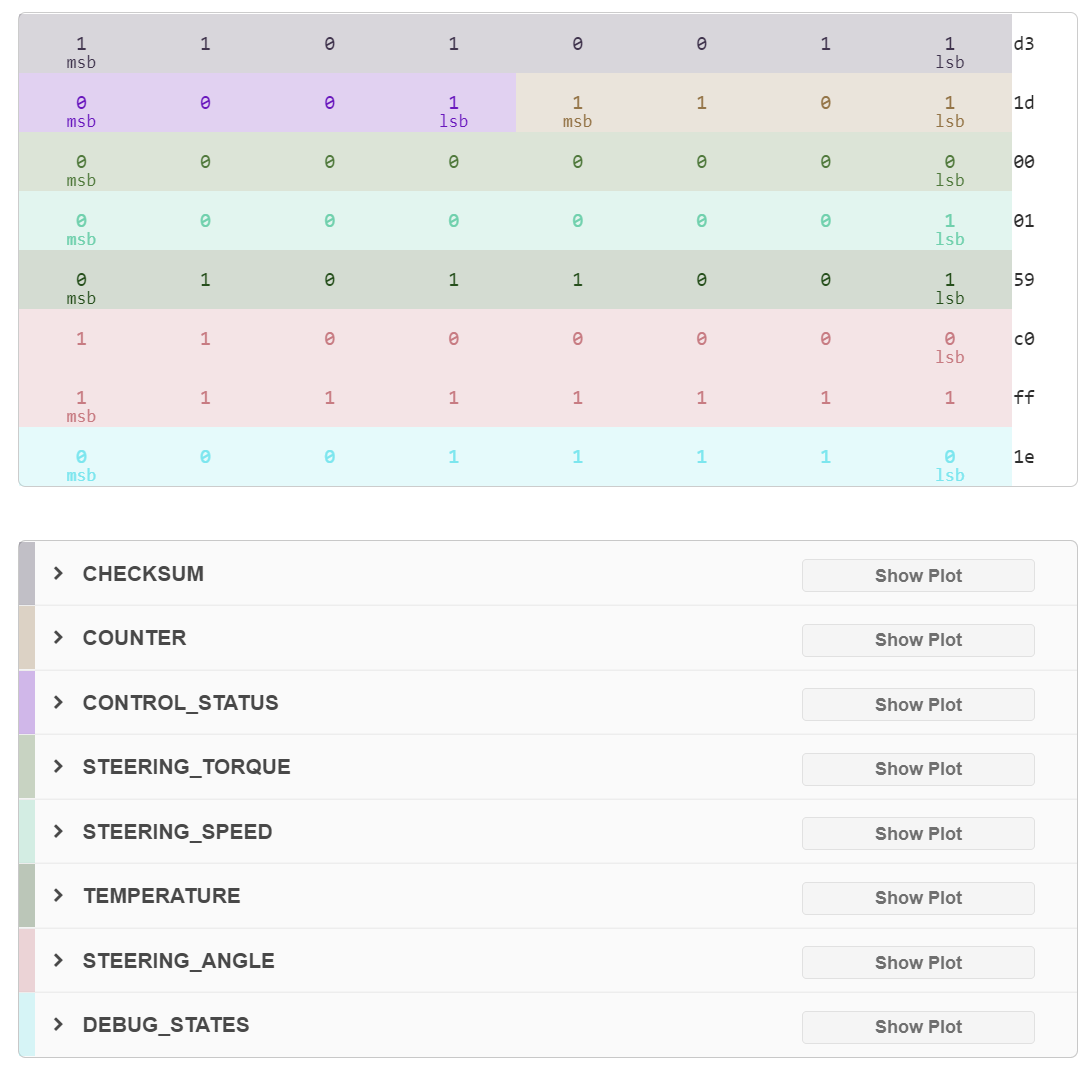

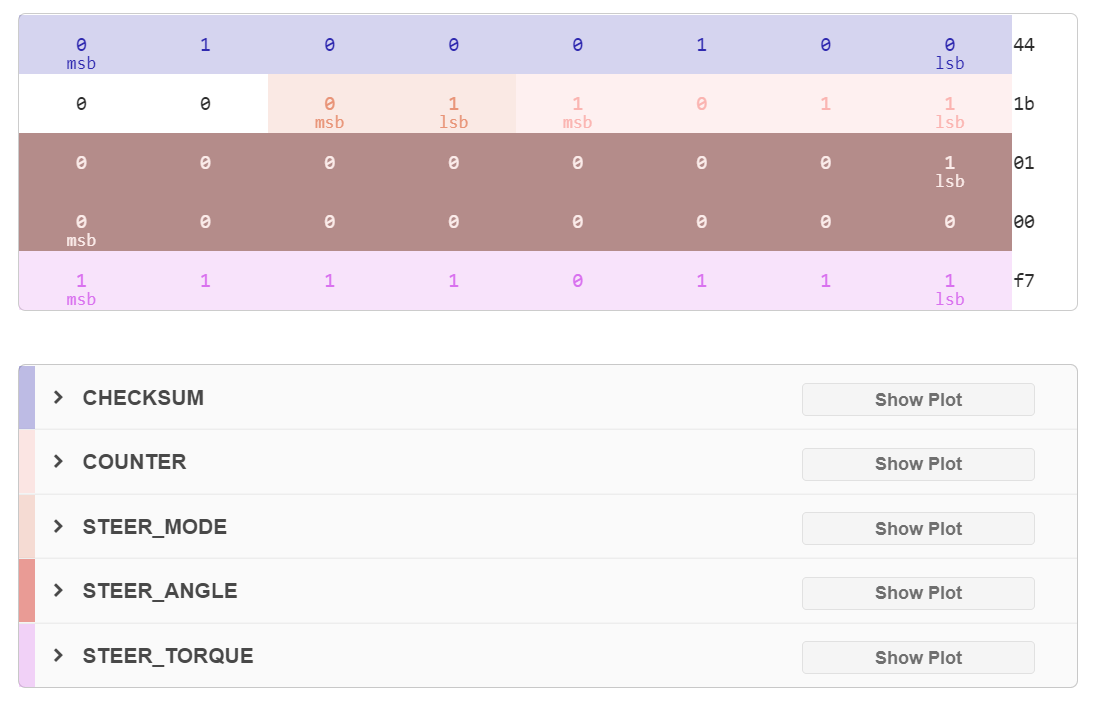

STEER_MODE 0 "Off" 1 "TorqueControl" 2 "AngleControl" 3 "SoftOff" ;SoftOff is a safe state that all steering actuators ideally should implement t satisfy some basic safetyDRIVER_TORQUEmoved to a separate message because almost certainly this wouldn't be ever sent by the motor actuator controller. I don't know if anyone uses it.Cabana view:

STEERING_STATUS

STEERING_COMMAND

Consistency check report from CANdb++: